Gas Turbine Controls is a combustion engine at the core of a power plant that can change flammable gas, or other fluid fills over to mechanical energy. This energy then, at that point, drives a generator that creates the electrical energy that moves along power lines to homes and organizations.

How Gas Turbines Produce Electricity

The gas turbine controls warm a combination of air and fuel at high temperatures to create electricity, making the turbine sharp edges turn. The turning turbine drives a generator that changes over the energy into electricity.

The gas turbine controls can blend with a steam turbine—in a consolidated cycle electricity plant—to make power very productively.

In this day and age, a tremendous measure of assets are legitimately committed to finding more up-to-date, more proficient, and more moderate approaches to make energy.

Albeit early forms of gas turbines were made as ahead of schedule as the year 50 AD, the gas turbine controls as a significant force maker came about not long before the turn of the twentieth century. They are consistently being improved to give solid energy networks throughout the planet today.

Parts of a Gas Turbine

Albeit the activities of gas turbine controls are intricate, there are three fundamental parts: the compressor, the burning framework, and the turbine. The compressor works by maneuvering air into the motor, then compressed and taken care of into the ignition chamber at up to a few miles each hour.

The burning system uses fuel injectors to infuse flammable gas into the ignition chamber, bringing about more than 2,000 degrees Fahrenheit. At long last, the combusting gas enters the turbine, where it turns pivoting sharp edges that thus turn a generator, creating power for various energy markets. This interaction additionally maneuvers more air into the compressor, restarting the cycle.

Kinds of Gas Turbines

Even though gas turbine controls all work with a similar fundamental interaction, there are contrasts between two significant kinds of turbines: hefty edge motors and aero-derivative motors. One principal difference is the pressing factor proportion, which is the proportion between compressor release pressing factor and inlet air pressure.

While the pressing factor proportion for weighty casing motors is typically under 20 psi, it is more than 30 psi regarding aero-derivative motors. Another distinction is that aero-derivative engines are, for the most part, minimized and utilized when less energy is required, and weighty edge motors are bigger and have a lot higher force age.

Notwithstanding, this additionally implies they have higher emanations and hence should be planned diversely to lessen outflows of toxins like NOx.

Heating and Cooling

Without accomplishing high temperatures, a gas turbine would not have the option to make energy effectively. Gas turbine controls can reach up to 2300 degrees F. As it may, numerous materials used to make the turbines can’t support this warmth.

To address this, some air from the compressor is utilized to cool significant parts of the turbine. Even though it might lessen by and large productivity, this system overhaul builds the system’s life expectancy.

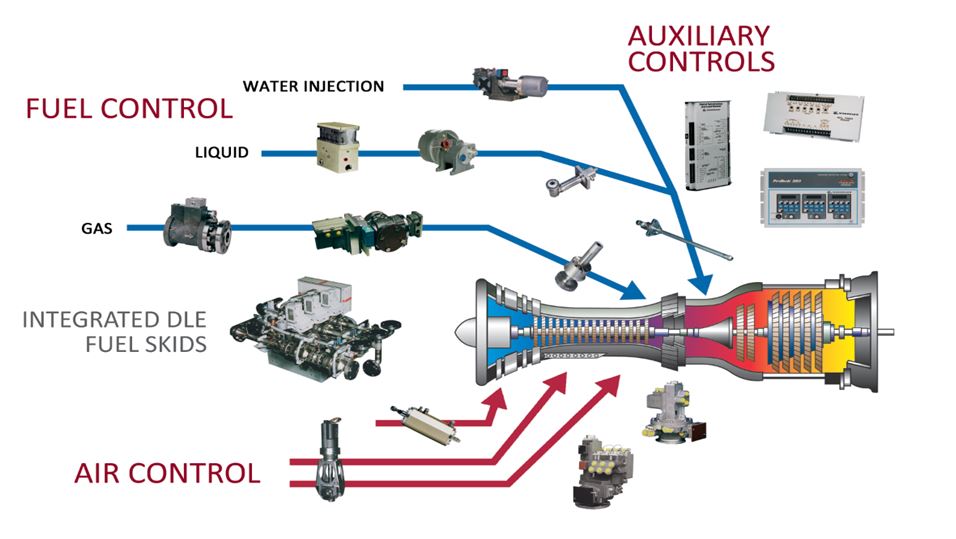

Gas Turbine Controls

Since gas turbines have a particularly massive yield of energy, progressed control frameworks and arrangements are fundamental for the security and productivity of the interaction. Many moved control systems can make or refresh controls for electro-pressure driven, simple electronic, or transfer and pneumatic based control systems.

These systems incorporate a DCS interface and a realistic administrator interface, turbine and compressor sequencing, and flood and limit control for compressor drives. Generator drives include total turbine control, moving and information logging, and synchronization and security.

Gas Turbine Uses

Varieties of gas turbines have been used by Leonardo Da Vinci, Nikola Tesla, and Sir Charles Parsons, and they have gone into everyday use in numerous fields today. These turbines are utilized to push for fly motors, for mass force creation, or in ships, trains, helicopters, and tanks. Few vehicles mean transport, and cruisers additionally use gas turbines.

Benefits of Gas Turbine Controls

Albeit no method for energy creation is 100% effective, there are numerous advantages of gas turbines over other energy arrangements. Since the gas creation costs are low, there is a lower operating expense than multiple different generators.

They likewise have less functional disappointment and vacation comparative with different arrangements. When burning regular gasoline rather than coal, these turbines again produce fewer fumes gas contamination than inside ignition motors, using the abundance air for more burning.

It is the case that gas turbines offer a practical and proficient energy arrangement. However, they can’t work without a viable control framework. You can look into the control system arrangements and see technical documentation about our full application line for more data.